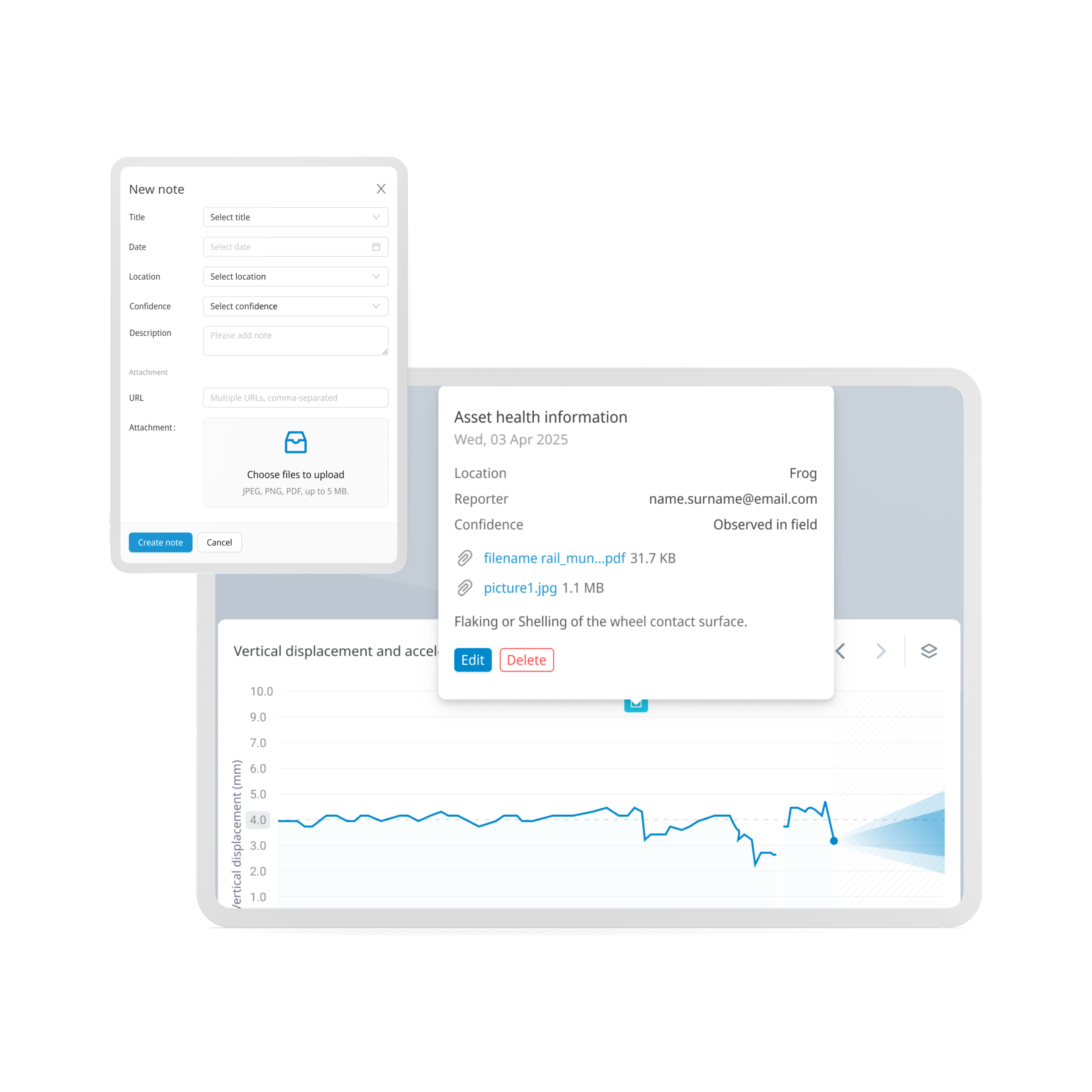

Asset Notes bridges the gap between field experience and data intelligence by linking on-site observations, inspection reports, and technician feedback with IoT and AI insights. It creates a unified digital record of each asset’s condition and history, giving teams clearer context for their decisions. With all relevant information in one place, maintenance and asset managers can better understand what’s happening on the ground, track changes over time, and act with greater confidence and precision.

Capacity meets AI

Railway is the hidden sustainability champion in transportation.

But with demand predicted to double by 2050, radical steps are needed

to ensure the resilience and competitiveness of the system on which millions rely.

AI can unlock sources of operational capacity and efficiency

previously unimaginable, fueling a true railway revolution.

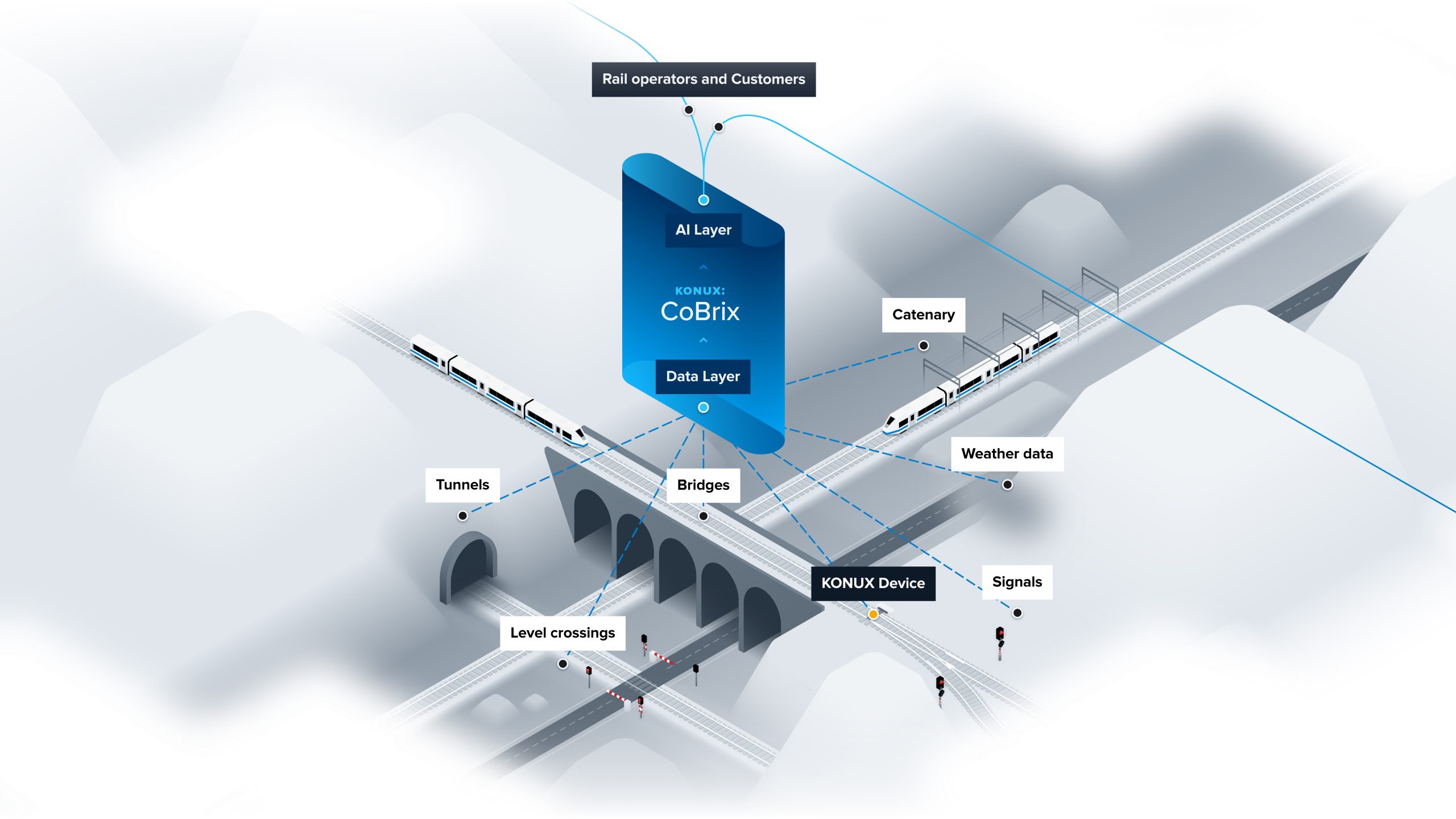

KONUX CoBrix is our modular Data & AI Platform designed to help partners co-create rail infrastructure solutions.

The railway industry is grappling with aging infrastructure, disconnected data systems, and siloed innovation. As a result, operators and technology partners often duplicate efforts and waste resources solving the same problems independently.

The railway industry is grappling with aging infrastructure, disconnected data systems, and siloed innovation. As a result, operators and technology partners often duplicate efforts and waste resources solving the same problems independently.

Solutions

Accelerating Railway Digitalisation

Enabling the rail ecosystem - together with KONUX

Learn moreRecent updates

Recent updates

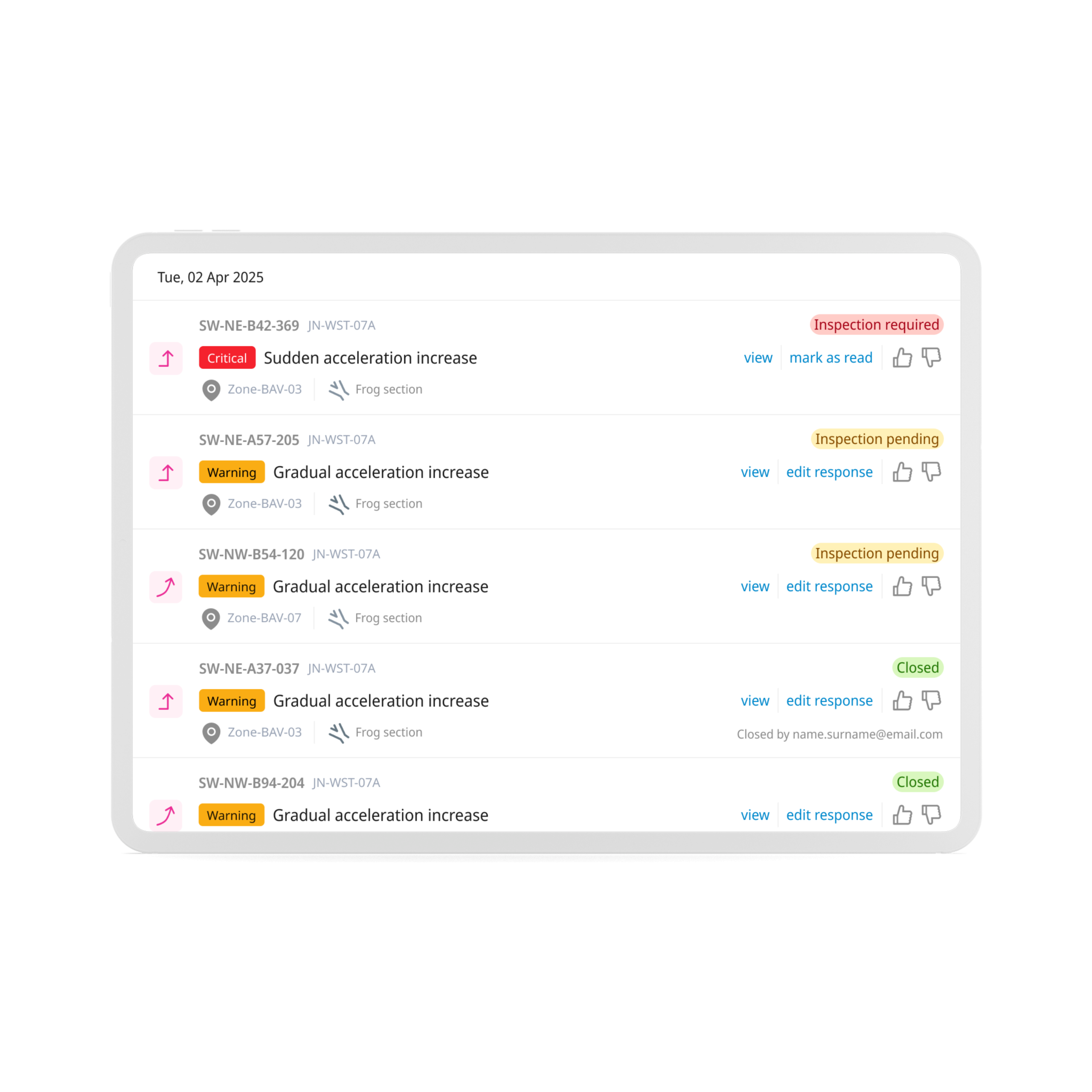

Smarter Frog Health for Clearer, Faster Decisions

KONUX Switch now offers smarter frog-health monitoring with a dual-layer model combining real-time alerts and a new AI-powered Reliability Score that predicts failure risk up to four months ahead. Trained on over 4,500 assets and 1.4 million train traces, it helps maintenance teams prioritise inspections, plan interventions more effectively, and make clearer, faster decisions.

Recent updates

A smart bridge between ground truth and intelligent decision-making

Recent updates

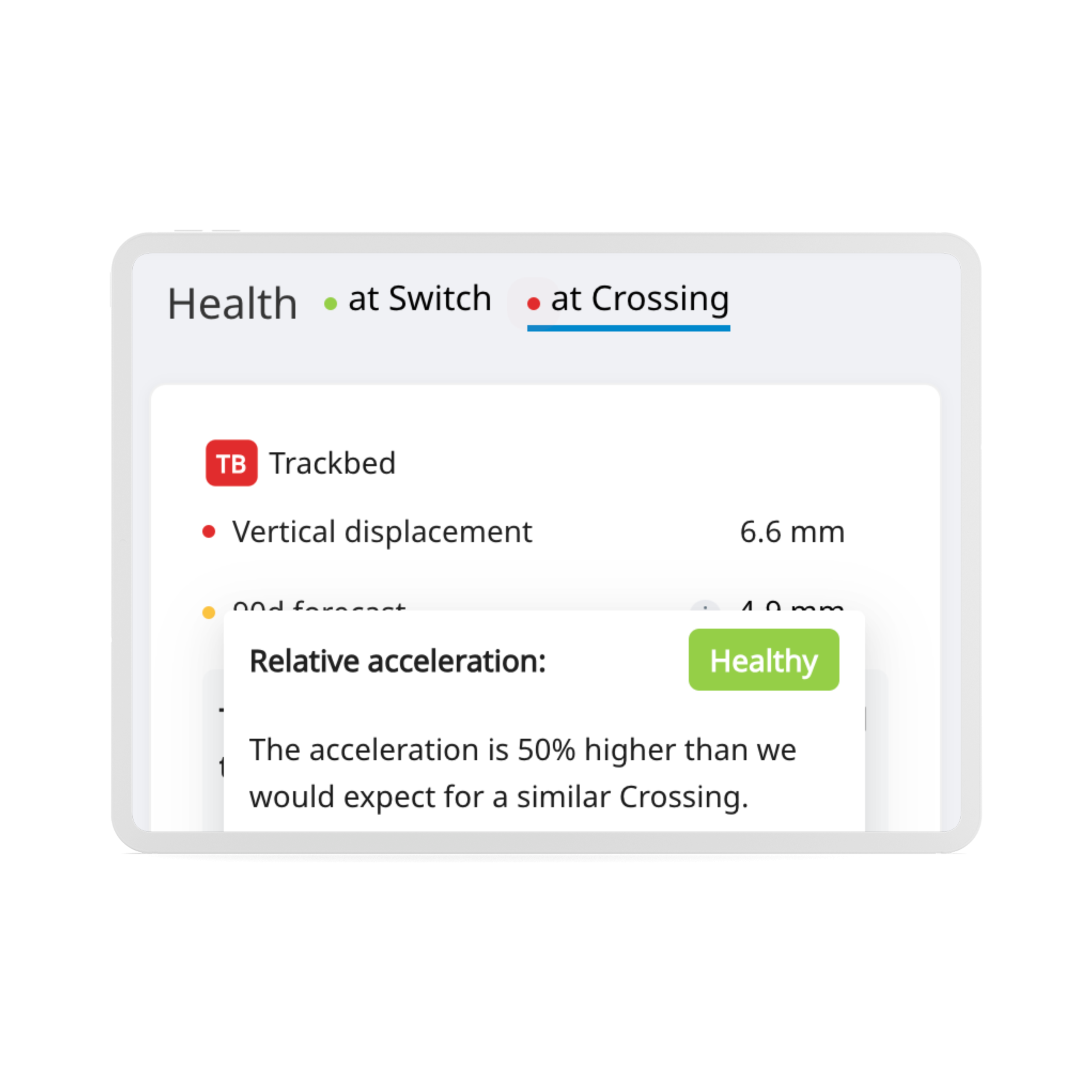

Smarter S&C Maintenance with Relative Acceleration powered by our Population Correction Models

- Moving Beyond Thresholds

- Asset Notes

- Population Correction Models

Events

See us at these upcoming events

Find out how we can

work together

Help drive the transition to sustainable mobility

The KONUX team is strongly driven by engineering talents, and complemented with an outstanding business team that dives deep into customer problems and technical challenges, and understands how we can build our product platform. We combine Silicon Valley digital thinking with German engineering.